HÖRL – where productivity inspires

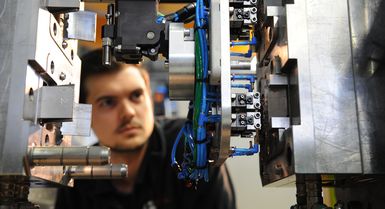

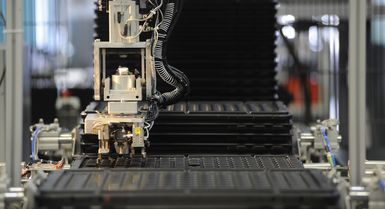

Every day we produce millions of components with state-of-the-art production equipment. Highest precision and continuous high quality are our requirements. In order to do justice to this, we have networked our production completely digitally.

All production processes are monitored and controlled centrally via a host computer system. With every deviation of the given production parameters, our specialists are informed in real time and can intervene immediately. As a result, we achieve maximum stable processes and implement a zero-defect strategy. The fully automatic assembly of individual assemblies into finished products as well as special individual demands on packaging are a matter of course for us. For our customers, we take over parts of the supply chain management right up to the just-in-time delivery of an assembly line.